High-accuracy Guide-pillar Die Spotting Machine YC Series

SpreX-80YC/1200YC

The high-standard configuration ensures the excellent performance of the machine. The main machining parts are processed by the imported machining center to ensure the machining accuracy of the mechanical parts. The shift-out track for lower template is the strengthened wear-resistant track with large range of dust-proof device. The hydraulic system adopts the optimized combination of high-performance imported hydraulic parts, where the oil pump is from Denison, a world-class brand, the hydraulic valve is from Vickers( USA) and Taiwan brands; the seals are from NOK and the control part is computer control system of special die spotting machine.

Design Focus

- The design of guide pillar structure and elastic template makes the high precision in the progress of high pressure mold pressing and the convenient adjustment of template parallelism.

- The moving part of the whole machine is install ed with oll-free and self-lubricating graphite copper sleeve guide,making the machine cleaner and more environmentally friendly.

- Practical and reliable fault detection, alarm and low-pressure mold protection functions.

- The lower worktable is equipped with high-precision positioning device and lifting device.

- Four mold closing oil cylinders make the force uniform and the deforrmation coefficient small.

- SIKO ( Germany )magnetoscale railing ruler is used to detect the moving position of midele seat, which makes the position more accurate.

- The mechanical safety protection device makes your mold and machine safer.

Choose Your Model

Installation Specifications

| Item/code | SX80YC | SX120YC | SX160YC | SX200YC | SX260YC | SX300YC | SX350YC | SX400YC | SX500YC | SX600YC | SX800YC | SX1000YC | SX1200YC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 1000 | 1400 | 1300 | 1800 | 2000 | 2200 | 2800 | 3000 | 3100 | 3500 | 4200 | 5000 | 6500 |

| B | 800 | 1100 | 1300 | 1500 | 1600 | 1800 | 2200 | 2000 | 2100 | 2500 | 3500 | 4200 | 4600 |

| C | 2320 | 3080 | 3320 | 3730 | 3740 | 4410 | 4880 | 4840 | 4940 | 5945 | 8485 | 9215 | 10015 |

| D | 1270 | 1720 | 2000 | 2200 | 2200 | 2680 | 2880 | 2960 | 3160 | 3560 | 4560 | 5220 | 5620 |

| E | 595 | 580 | 430 | 430 | 430 | 610 | 610 | 320 | 320 | 320 | 470 | 475 | 475 |

| F | 4185 | 5380 | 5750 | 6360 | 6370 | 7700 | 8370 | 8120 | 8420 | 9825 | 13515 | 14910 | 16110 |

| G | 1850 | 2395 | 2680 | 2880 | 3080 | 3510 | 4110 | 4390 | 4550 | 5000 | 5940 | 6820 | 8590 |

| H | 765 | 765 | 765 | 765 | 765 | 715 | 715 | 715 | 715 | 715 | 715 | 715 | 715 |

| I | 2615 | 3160 | 3425 | 3625 | 3845 | 4225 | 4826 | 5105 | 5265 | 5715 | 6655 | 7535 | 9305 |

| J | 22 | 22 | 28 | 28 | 28 | 36 | 36 | 36 | 36 | 36 | 42 | 42 | 42 |

| K | 570 | 715 | 805 | 875 | 875 | 985 | 1035 | 1085 | 1155 | 1275 | 1610 | 1665 | 1665 |

| L | 775 | 995 | 1085 | 1175 | 1175 | 1305 | 1580 | 1625 | 1730 | 1875 | 1995 | 2184 | 2184 |

| M | 1485 | 2090 | 2210 | 2520 | 2520 | 3025 | 3360 | 3320 | 3370 | 4180 | 6120 | 6590 | 7140 |

| N | 440 | 670 | 640 | 750 | 750 | 910 | 1030 | 990 | 990 | 1350 | 1790 | 2130 | 2330 |

| O | 940 | 1280 | 1500 | 1700 | 1700 | 2060 | 2260 | 2260 | 2400 | 2800 | 3720 | 4300 | 4700 |

| P | 1210 | 1645 | 1860 | 2060 | 2260 | 2550 | 3150 | 3340 | 3470 | 3900 | 4600 | 5400 | 6900 |

| Q | 3690 | 4630 | 5240 | 5695 | 5780 | 6860 | 7205 | 7405 | 8525 | 9275 | 11855 | 12300 | 13400 |

| R | 150 | 200 | 200 | 200 | 200 | 200 | 400 | 400 | 400 | 400 | 100 | 100 | 100 |

| S | 1150 | 1500 | 1700 | 1900 | 1900 | 2300 | 2500 | 2500 | 3000 | 3200 | 4000 | 4300 | 4700 |

| T | 1000 | 1300 | 1500 | 1700 | 1700 | 2100 | 2100 | 2100 | 2600 | 2800 | 3900 | 4200 | 4600 |

| HA | 500 | 670 | 750 | 800 | 800 | 900 | 900 | 1100 | 1100 | 1100 | 1750 | 1450 | 1450 |

| LA | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| LB | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| WA | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| WB | 800 | 800 | 800 | 800 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

* Note: technical parameters are subject to change without notice.

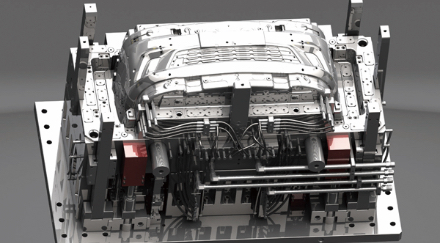

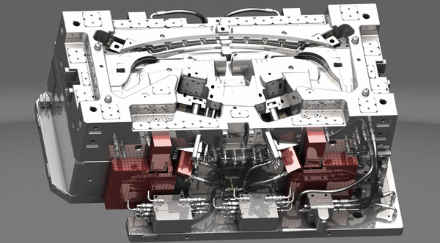

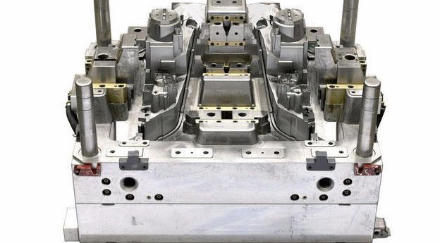

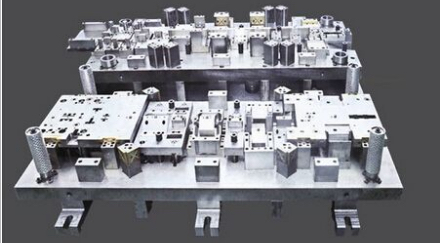

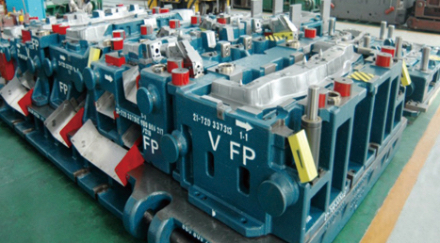

Related Applications

SpreX's products have a wide range of applications, including plastic molds, die casting molds,stamping molds, injection molds, creating more value space for customers.

Injection Molding

Die Casting

Stamping

Stamping

Stamping